Finding Bespoke Suppliers in the UK

For start-ups and product developers in the UK, finding the right manufacturing and development partners is essential to getting a product from concept to market efficiently. You’ll need suppliers who can offer custom, high-quality, and responsive services tailored to your unique requirements.

Here’s what to consider when looking for bespoke suppliers in these areas, and where to find trusted support.

1. Injection Moulding: Precision and Flexibility Matter

Injection moulding is ideal for producing consistent plastic parts at scale. Whether you're creating housings, enclosures, or internal structural parts, you’ll want a UK-based supplier that offers:

· Small-batch and low-volume options

· A range of mould materials (aluminium, steel, etc.)

· Design-for-manufacturing (DFM) support

· Fast turnaround for initial tooling

Working with a local UK supplier gives you the advantage of easier communication, quicker iterations, and better quality control. For start-ups especially, suppliers offering prototype moulding before full-scale production are invaluable.

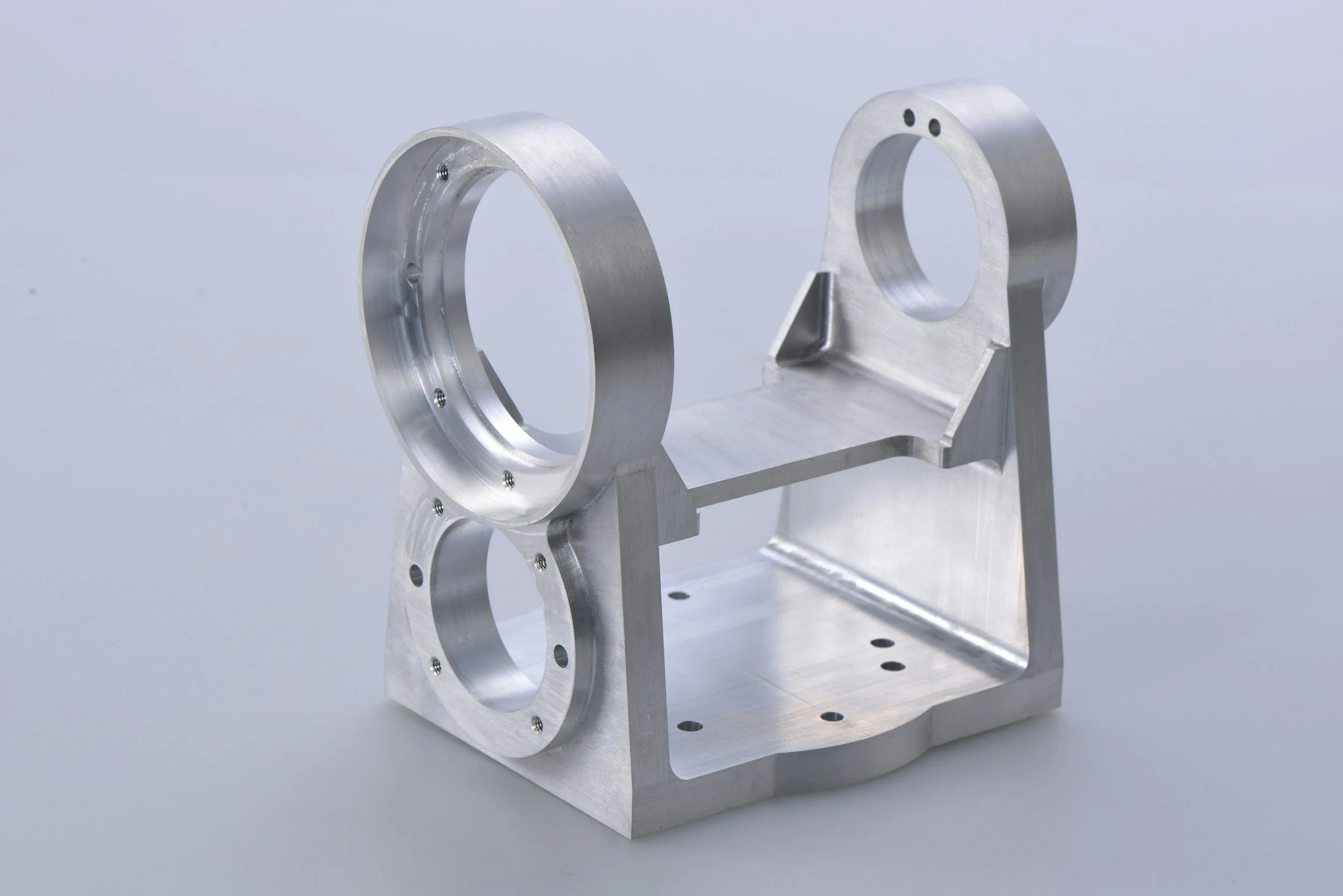

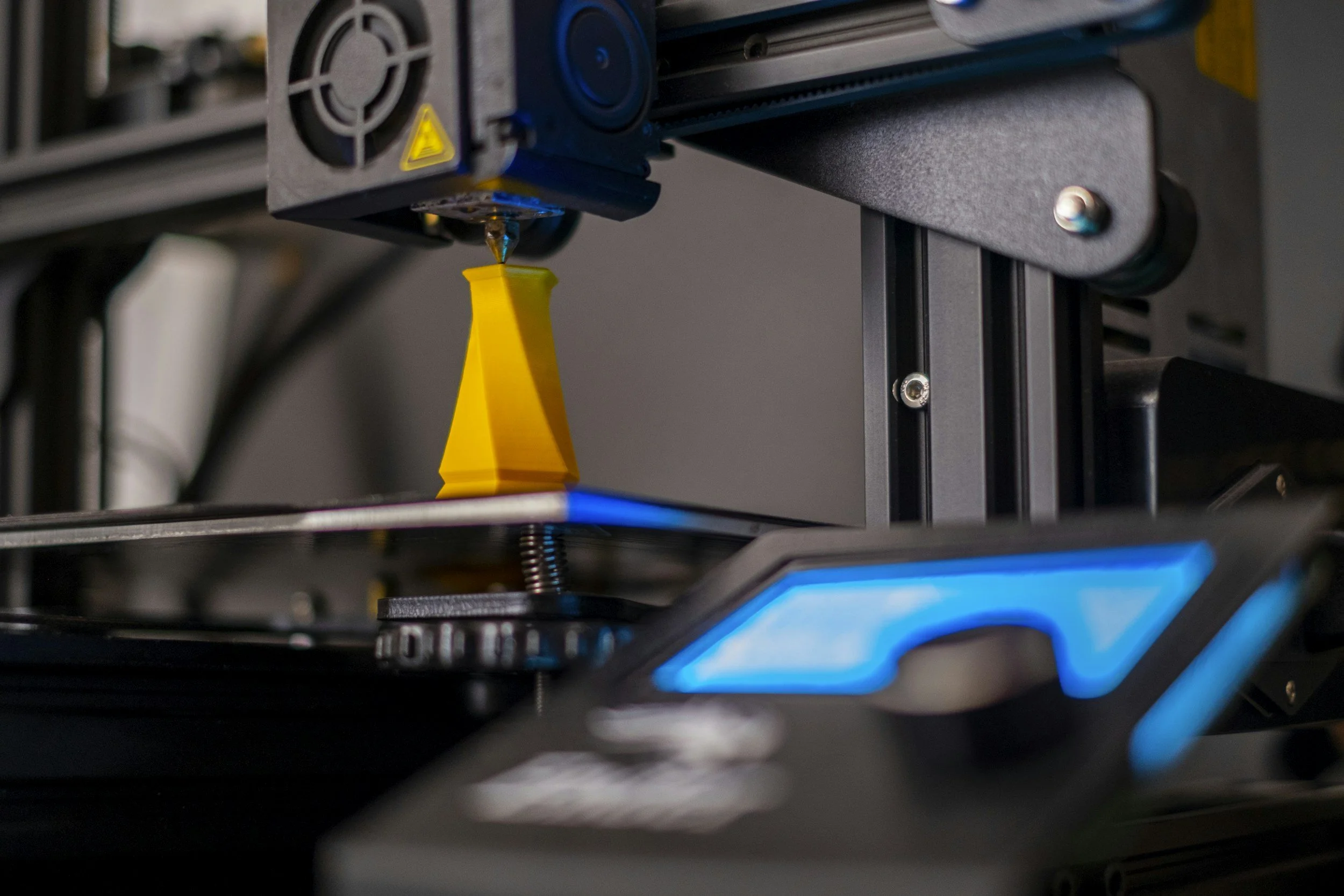

2. Rapid Prototyping: Speed with Accuracy

In the product development cycle, speed is often critical. Rapid prototyping services help you test ideas quickly before committing to costly manufacturing.

Look for services offering:

· 3D printing (SLA, SLS, FDM)

· CNC machining

· Vacuum casting

· Quick-turn fabrication

A good prototyping partner will also be able to advise on material selection and tolerance constraints and ideally support both visual models and functional prototypes. UK-based providers often allow for faster iteration loops and easier on-site reviews, which can make a significant difference in your development timeline.

3. PCB Design and Manufacture: From Idea to Circuit

If your product requires electronics, choosing a supplier experienced in 1–4 layer PCB design and fabrication is key. While basic PCBs are relatively straightforward, ensuring quality and functionality in custom designs is another matter.

· Your ideal supplier should offer:

· PCB layout and design support

· Gerber file validation

· Quick turn prototyping

· Assembly (SMT/THT options)

· Testing and debugging services

Being able to consult with a UK-based engineer during the design process can help avoid common pitfalls and ensure your board is ready for manufacturing and CE compliance.

4. End-to-End Support is Invaluable

Often, the best results come from suppliers who don’t just execute a task, but also collaborate on design improvements, help reduce cost, and optimise performance. That’s why choosing a team with engineering expertise—not just machinery—makes a difference.

Whether you’re launching your first MVP or scaling up an existing product, the value of a multi-disciplinary supplier who can handle mechanical, electronic, and prototyping work under one roof shouldn’t be underestimated.

Nexus Formations: UK-Based Expertise for Startups and Product Teams

At Nexus Formations, we offer a comprehensive range of services tailored to innovators, engineers, and entrepreneurs. Our team provides:

· Custom injection moulding solutions

· Rapid prototyping using modern manufacturing technologies

· 1–4 layer PCB design, assembly, and testing

· Design consulting and optimisation advice

What sets us apart is our hands-on engineering support, provided by experienced British engineers who understand both technical and commercial challenges faced by startups. Whether you need help turning an idea into a prototype, or you’re ready to refine and scale your design, we’re here to help every step of the way.

Contact us.

We have experts ready to discuss your custom needs.

Fill out the form below, or Email:

sales@nexusformations.co.uk